Reducing Unaccounted-for-Effluent in a Common Effluent Treatment Plant by 66.4% using EverSense for WaterMAP

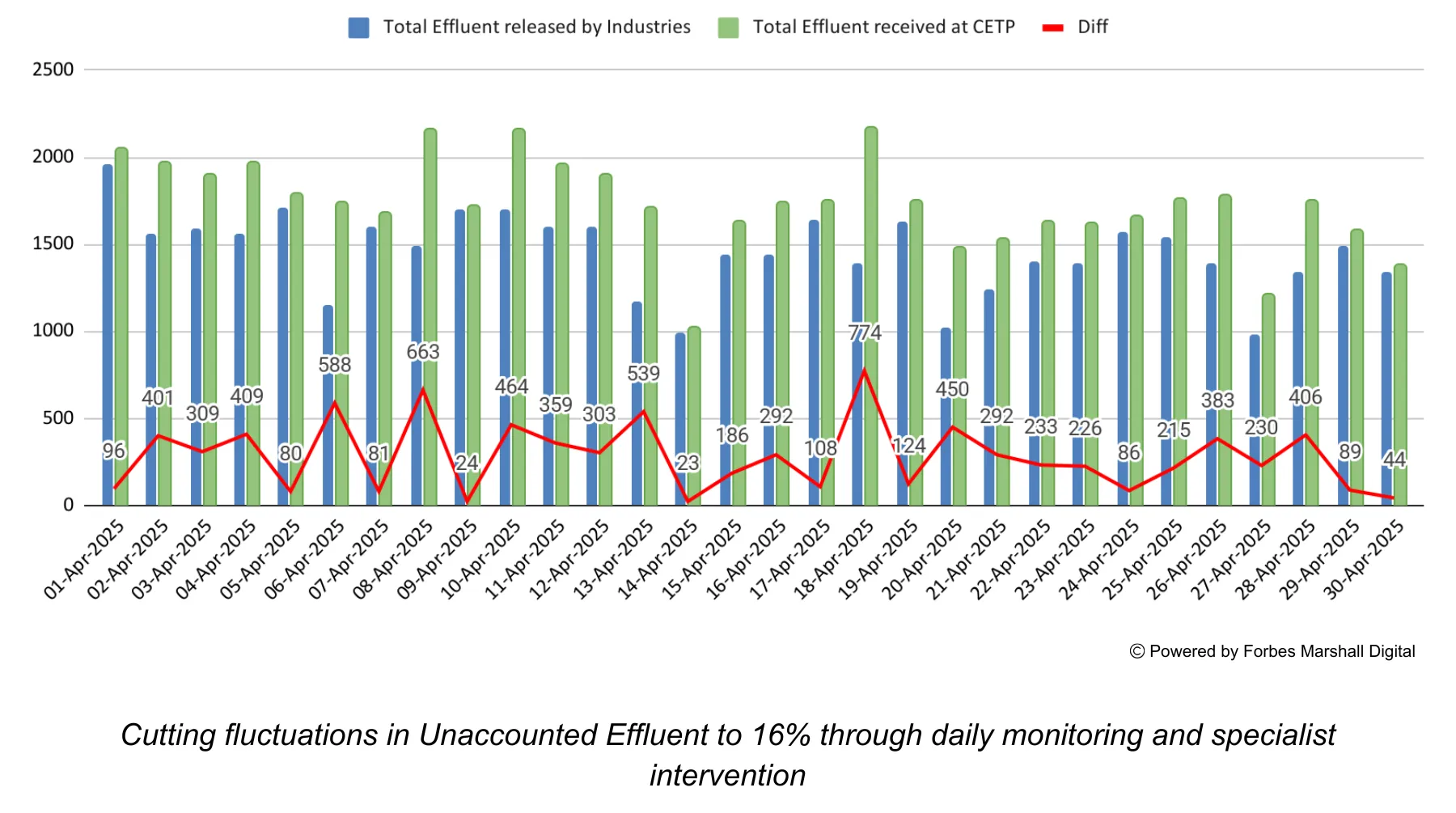

A Common Effluent Treatment Plant (CETP) in South India was facing wide variations in the effluent volumes received from its 72 member industrial plants. While the expected average effluent discharge from each industry was around 20 m³/day, nearly 50% of this flow remained unaccounted for. To address this challenge, our Forbes Marshall Digital partnership with this CETP began in March 2024 with a shared objective: to improve effluent accountability and establish a more cost-effective treatment process. Using EverSense for WaterMAP, a Forbes Marshall Digital solution, the goal was to decrease the gap in effluent discharge measurement and reduce the Unaccounted-for-Effluent (UAE) between the tanneries and the Common Effluent Treatment Plant (CETP) from 50% to below 10%, thereby reducing the overall cost of treatment for the CETP.

Products

Associated Services

Process Optimization

Improving Uptime