Steam is used in breweries for heating, cleaning, and pasteurizing. A large proportion of the

steam is used in the extraction of sugars and flavours in the mashing process and for wort

boiling. These two processes alone account for up to 50% of the connected steam load.

Other areas of the brewing process that use steam include pasteurisation, bottle washing

and CIP systems.

Fuel used for steam generation accounts for more than 40% of the total utility cost in a

Brewery and therefore presents the largest opportunity to drive conversion cost reduction.

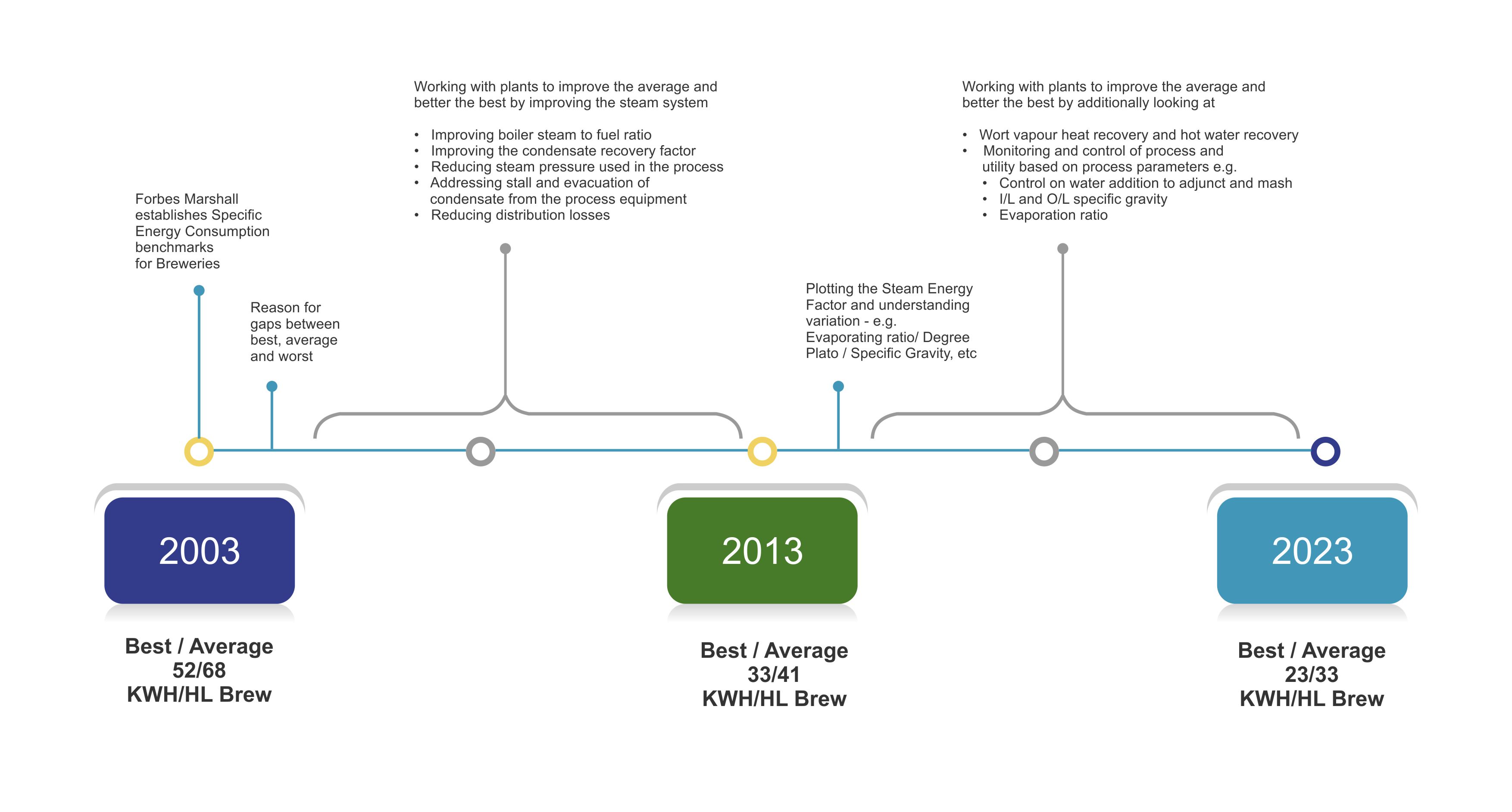

Our efforts over the last two decades in this direction has led to significant reduction in the

energy consumption per hectolitre of beer produced. We pioneered the concept of specific

energy benchmarking in breweries in India in 2003 by studying the energy consumption

patterns across breweries in India and identifying gaps leading to higher energy

consumption. By partnering with plants across the industry and addressing these gaps we

have reduced the energy consumption benchmark by over 40%.

Over the years, to meet challenging new targets for conversion cost reduction, our solutions

have evolved to not only focus on optimising the steam and condensate network but also on

optimising the process by looking at factors like wort vapour heat recovery for hot water

generation, optimising the energy tank and precisely controlling the utility based on the

process parameters e.g. controlling water addition to the adjunct, precisely maintaining the

evaporation ratio / degree plato during wort boiling. Besides reducing the energy

consumption per hectolitre of brew we also provide solutions for water and waste water

treatment.

Our own observations suggest that with available and cost effective technology there are still

opportunities to reduce energy consumption by about 21% on an average globally across

breweries.