Air is free, but compressed air is not free. Plug air leaks to save electricity.

Though air is free, compressed air is not. It is in fact, one of the most expensive energy sources and is used in many manufacturing facilities. The cost of generation, however, is often overlooked by plant managers, maintenance, and production.

The cost of compressed air can be easily calculated by knowing the Free Air Delivery (FAD) capacity, motor power consumption and operating pressure.

Consider an example of a 1500 Scfm Compressor operating at 7 barg. The compressor motor with a rating of 250 KW would require 1 KW to generate 6 Scfm. Taking the cost of electrical power as Rs. 5/- per KW, 6 Scfm will cost Rs. 5/-; hence daily cost of compressed air assuming 12 hrs of operation is close to Rs.45 lakhs annually!

As a thumb rule the cost of electricity consumed by an air compressor annually is equal to its cost. Compressed air leaks are too expensive to ignore. Plug them to save electricity and cost.

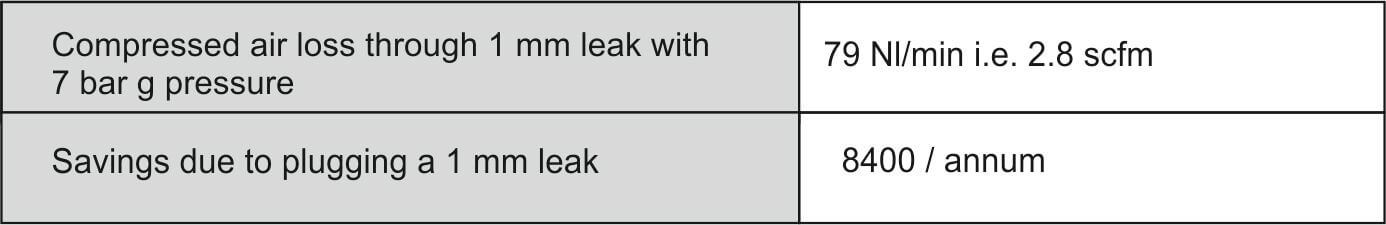

Illustration:

(SCFM (Standard Cubic Feet per Minute) is the volumetric flow rate of a gas corrected to "standardized" conditions of temperature, pressure and relative humidity, thus representing a precise mass flow rate.)