Air vents facilitate reduction in batch time, enable higher process efficiency and operate satisfactorily when they are installed at the top most points in the steam distribution network.

When steam is first charged into a pipeline after a period of shutdown, the pipe is full of air. During running conditions, small amounts of air and non- condensable gases will enter with the steam. When the steam condenses, the gases that are present with steam, will accumulate in pipes and heat exchangers.

A film of air only 0.025 mm thick may resist as much heat transfer as a wall of copper 400 mm thick. It is therefore very important to eliminate air. Doing so allows optimum heat transfer to take place in the heat exchangers, allowing efficient operation and thus saving fuel.

Automatic air vents for steam systems should be fitted above the condensate level. This would ensure air reaches the vents and is discharged. The best location for air vents is at the end of the steam mains.

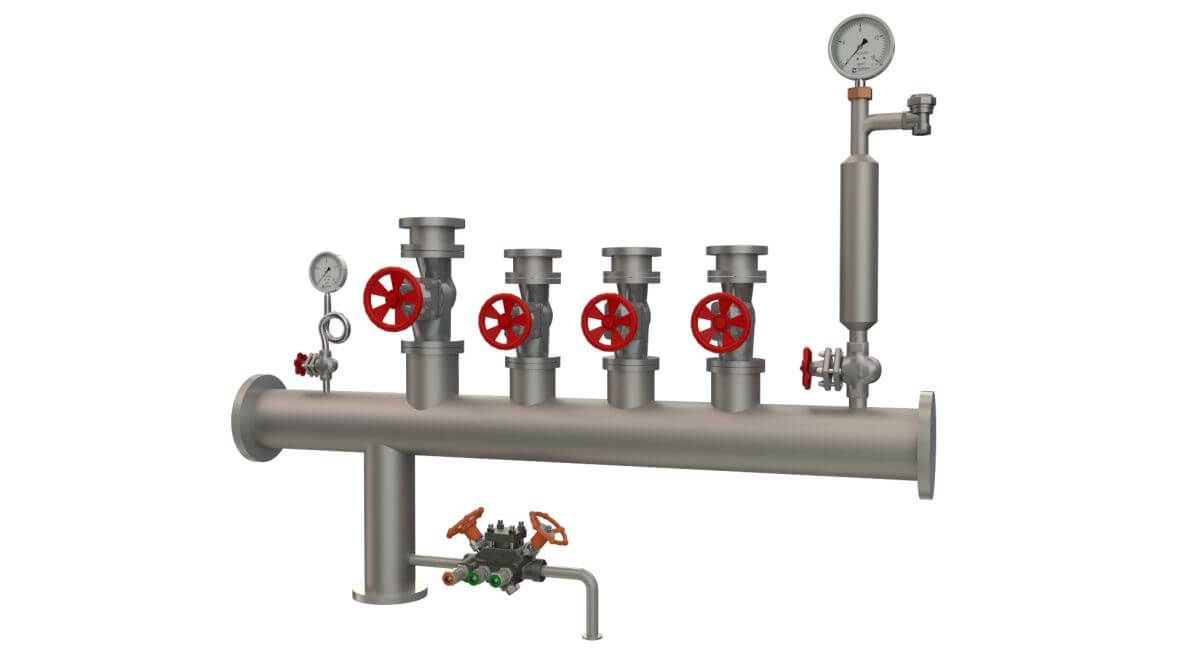

The diagram above shows ideal air vent installation on a steam header

In addition to air venting at the end of steam mains, vents can also be installed

- In parallel with buckets trap as these traps are sometimes slow to vent air on start-up.

- Where there is large steam space (such as autoclave), and a steam/air mixture can affect process quality.