A Steam Trap is an integral part of a steam system. Steam traps play the important role in maintaining the productivity and efficiency of steam system. This exhaustive guide answers all the questions one might have about steam traps, their working principles, troubleshooting etc.

What is a Steam Trap?

A Steam trap an automatic drain valve which distinguishes between steam and condensate. A steam trap holds back steam & discharges condensate under varying pressures or loads. The steam traps should have good capacity to vent out air and other non-condensable gases quickly while holding back the live steam.

Why Steam Traps are used?

Steam generated by a boiler contains heat energy which is used to heat the product. When steam loses it energy by heating the product, condensate is formed. Also, a part of energy contained by steam is lost through radiation losses from pipes and fittings. After losing this heat, steam gets converted into condensate. If this condensate is not drained immediately as soon as it forms, it can reduce the operating efficiency of the system by slowing the heat transfer to the process. Presence of condensate in a steam system can also cause physical damage due to water hammer or corrosion.

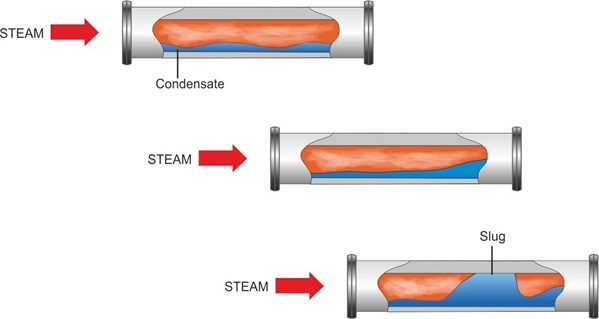

As shown in the accompanying sketch, the condensate accumulates in the bottom of a horizontal pipe with steam passing over it. As the condensate builds up, it can form a solid slug of incompressible water traveling at high velocities. When the slug of water is suddenly stopped by a pipe bend, fitting or a valve, it can result in mechanical damage to the pipe or fitting.

It is equally important to remove air and other non-condensable gases from the steam system for four important reasons.

(1) On start-up, steam enters the system only as fast as the air is vented.

(2) An air steam mixture has a temperature well below steam temperature lowering the heat transferred.

(3) Air is an insulator and clings to the surface of the pipe or vessel causing slow and uneven heat transfer.

(4) Dissolved in condensate, the non-condensable gases from acid which corrode the system.

Types of Steam Traps: Based on working principle

Over the period, different types of steam traps have been developed to suit different applications. The essential property of a steam trap is to be able to distinguish between steam and condensate. Different types of steam traps employ different working principles and mechanisms to distinguish between steam, condensate and air. When classified according to these operating principles, each design has advantages and limitations which must be considered while selecting a steam trap for a specific application.

Generally, based on the principle used to distinguish between steam and condensate, steam traps are categorized as follows-

Density Operated-Mechanical Traps

Density operated or mechanical types of steam traps distinguish between steam and condensate based on difference in their densities. Steam is always lighter and hence, has a density much lower than condensate. A mechanical type of steam trap will allow only the heavy condensate to get discharged and hold back the steam.

As we have seen, quick removal of air and other non-condensible gases is essential for proper running of steam system. Float traps come with an optional air vent which quickly removes air and other gases during start ups.

There are two main types of mechanical steam traps which are commonly used.

a. Ball Float

Float traps or ball float traps are ideal for process heating applications. Float traps are designed in such a way that the valve seat is always submerged under water preventing any steam loss. The discharge is continuous and modulates with the condensing rate. It is unaffected by changes in inlet pressure. A separate thermostatic air vent independently purges air giving a fast start-up.

Principle of Operation

Air entering the trap is immediately discharged through a high capacity auxiliary air vent.

As condensate enters the trap body, the ball float being hollow, floats over the condensate. As condensate level increases, condensate causes the ball float to rise and place the modulating discharge valve in a position that will pass the condensate continuously as it enters the trap. The condensate level in the trap body is maintained above the discharge valve to provide seal against the loss of steam.

Advantages of Float Traps

- Discharge condensate continuously as rapidly as it forms

- High air venting capacity through auxiliary balanced- pressure air vent, which is self-adjusting for varying steam pressures.

- High thermal efficiency at both light and heavy loads. Continuous modulating discharge does not create pressure disturbances, which may affect control in air heating coils, shell and tube exchanges, etc.

- Steam lock release (S.L.R) Facility available

- Inline inlet and outlet facility, easy installation at low cost. Also available with vertical inlet & outlet connections

- Robust, fair resistance to water hammer.

- Wide range of orifices to suit inlet pressure.

Limitations

- Cannot be used on high degree of superheat.

- Applications subjected to freezing must be protected with insulation & SLR

- Water hammer can damage float

b. Inverted Bucket Traps

As the name explains, inverted bucket traps have an inverted bucket inside them. These are mechanical type of steam traps working on the principle of buoyancy.

Working Principle

1. Initially, the bucket is resting at the bottom of the steam trap and the valve seat is wide open. At star-up, air will enter the steam trap and will be discharged out through the bleed hole.

2. As condensate enters the trap, it forms a water seal inside the body. The weight of the bucket keeps the valve off its seat and so condensate can flow around the bottom of the bucket and out of the trap. Under low load or super heat conditions, the trap may need to be ‘primed’ with water before system start-up.

3. When steam enters the underside of the bucket, the bucket becomes buoyant and rises. This positions the valve lever such that the valve gets closed.

4. The bucket will lose its buoyancy as a part of the steam under the bucket condenses due to radiation losses and the remaining steam escapes through the vent hole. The weight of the bucket will pull the valve off its seat and the cycle is then repeated.

5. Inverted bucket traps discharge condensate intermittently and at steam temperature

Advantages

Resistant to water hammer

Disadvantages

Low loads or high super heat conditions can lead to loss of water seal. In such situations, the trap will vent live steam.

- Poor air venting capability.

- Intermittent discharge of condensate.

Thermostatic Steam Traps work on the temperature difference between steam and condensate. Condensate is at a temperature lower than the steam being used. Thermostatic type of steam trap has a port which is opened or closed based on the temperature of the inlet fluid. If the temperature is above the specified range, the port is closed. The port open when The temperature of the fluid falls down below the previously specified value.

Since air and other gases have a temperature much lower than that of steam, these steam traps can also be used as air vents.

Based on the actual working mechanism, they are classified as -

a. Balanced Pressure Thermostatic

b. Thermostatic

c. Liquid Expansion

d. Bimetal Expansion

Thermodynamic steam traps are operated by the principle of thermodynamics. The main principle behind the operation of thermodynamic steam traps is Bernoulli's principle.

Thermodynamic Traps are the most widely used steam traps for removing condensate from main lines largely due to their small size, wide pressure range, one moving part, and resistance to water hammer and corrosion. Because operation of each model depends on the manufacturer’s seat and disc design, results obtained by the user may vary widely.

Understand how Thermodynamic Steam Traps work

Go to our steam engineering Knowledge Bank