Whilst it is desirable to return the maximum amount of condensate to the boiler, it is essential to ensure that it is clean. Even low levels of contamination can cause foaming, scaling, or corrosion.

If carryover of boiler water with the steam occurs, then the product can become contaminated, resulting in expensive lost production. Continuous condensate monitoring with the condensate contamination detection system can protect the boiler, ensure product quality, and maximize energy and water savings.

System Components

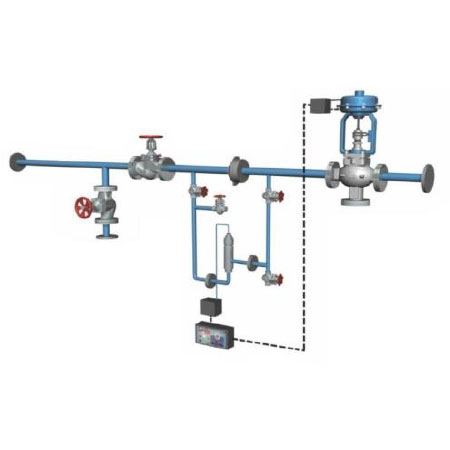

The system comprises a sensor chamber with conductivity sensor and temperature sensor, mounted in a condensate line bypass. The sensors are connected to a low range controller that constantly monitors and displays the conductivity level.

The Controllers

The controllers have two relay outputs, one of which is normally used to divert the condensate flow, and the other to operate an alarm. Other features include a 0/4- 20 mA output, and a temperature probe input facility. The wall mounted pH/ conductivity controller is with a digital display and push buttons for simple commissioning, calibration, and operation.

Working

The condensate contamination detection system monitors and displays the conductivity of the condensate. It automatically diverts the condensate to drain instead of back to the boiler system should the level rise above a pre-selected set point.

When the conductivity drops, the condensate is allowed to return to the boiler system, thus minimizing heat and water wastage, as well as avoiding the possibility of contaminating the feedwater.

Note: Though the system can detect very small changes in conductivity, it will not detect the presence of contaminants that do not affect conductivity, such as oils, fats, and sugars. If in any doubt, carry out a test on known clean condensate and known contaminated condensate, comparing conductivity.

Alternative valve layout: Two 2-port valves may be used instead of a 3-port diverter valve. An isolating valve in the condensate return line may be wired to close on detection of a high conductivity, and a dump valve in the condensate drain line wired to open at the same time.

User Benefits

- Avoids boiler damage and product contamination.

- Temperature compensation sensor gives accurate results regardless of condensate temperature.

- Minimizes energy wastage.

- Conserves expensive treated water.